COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Case Details

Project Overview

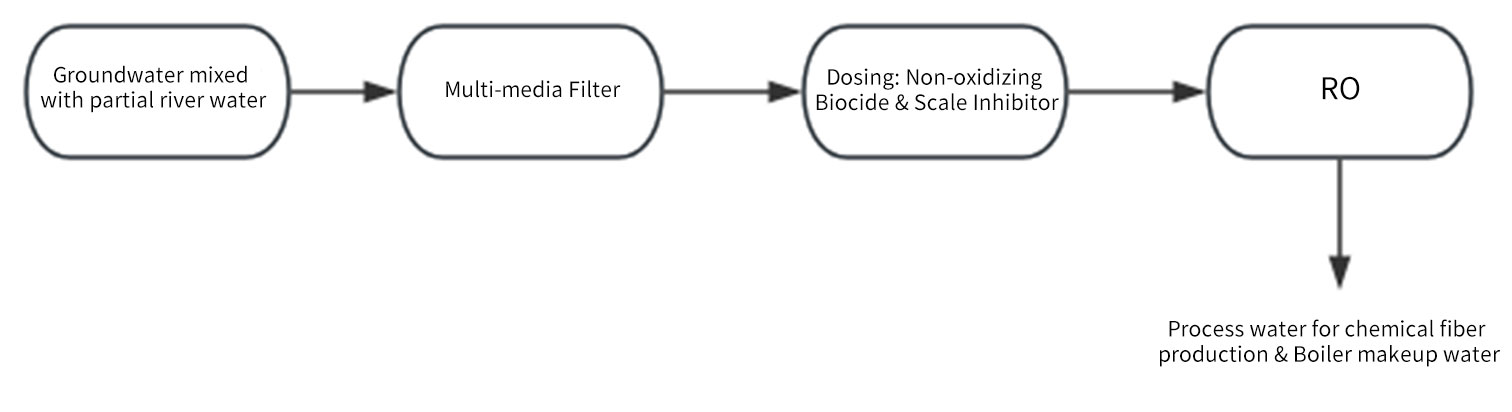

This water reuse project uses surface water as its feed source. Through pretreatment, the produced water is utilized as process water for chemical fiber production and boiler makeup water. The factory began using KeenSen membrane elements since 2017, with a cumulative replacement quantity of 2,000 units. In 2022, the project continued using KeenSen BW-8040FR fouling-resistant membrane elements. The reverse osmosis system employing KeenSen membrane elements in this water production plant operates stably, currently maintaining a salt rejection rate exceeding 98%. Both the produced water flow rate and quality consistently meet the owner's requirements.

Treatment Process

Project Information

| Model |

Flux Design LMH |

Recovery Rate % |

Operating Pressure MPa |

Salt Rejection % |

Array (Qty) |

| BW-8040FR | 25 | 75 | 0.7-1.2 | 98.7 |

13:7 Six-core installation |

No. 370, Minghu Road, Donghong Street, Xiangjiang New Area, Hunan,China

Scan the QR code to follow the WeChat official account