Product quality assurance

KeenSen Technology Co., Ltd. (Here in after referred to “KeenSen”)provides customers with the following limited quality guarantee for its reverse osmosis and nanofiltration products, including flat sheet and membrane elements.

1. Manufacturing Process And Material Warranty

KeenSen ensures that the RO and NF membrane element without defects on raw material and manufacturing process. KeenSen provides 12 months quality guarantee from the date of cargo receipt abiding by the correct operation and maintenance of the membrane element technical documents. If there is any quality problems caused by the manufacturing process or raw material, after KeenSen or a third party quality testing institution's inspection. KeenSen will provide replacement or free repair service.

2. Initial Performance Warranty

According to the test conditions on KeenSen brochures, KeenSen RO and NF membrane element ensure has the same specified initial permeate flow and rejection rate as the brochures described. If any membrane element can not achieve the described initial performances, after KeenSen or a third party quality testing institution's inspection. KeenSen will provide replacement or free repair service, meanwhile, bearing the freight.

3. Performance Warranty

Within the three-year guarantee period, according to the test conditions stipulated in the latest KeenSen brochure, KeenSen provides the following performance guarantees for RO and NF membrane elements :

(1) Salt Passage【Salt Passage =(1-Rejection Rate)*100%】doesn't exceed double of value described in product manual (RO membranes are subject to standard NaCl solution, NF membranes are subject to standard MgSO4 solution).

(2) The average permeate flow is not lower than 70% of initial permeate flow (RO and NF series are subject to standard NaCl solution).

If any membrane element has above performance problems within the warranty period, after KeenSen or a third party quality testing institution's inspection. KeenSen will provide replacement or free repair service.

4. Warranty Period

KeenSen provide 36 months performance warranty of RO and NF membrane element. The warranty expiry period shall be any following condition coming first.

(1)From the date of membrane element initial operating, that means, the output water from pretreatment system enter into RO and NF membrane system.

(2) From 180 days after the date of shipment of membrane element.

(3) Within 7 working days after customer receipt membrane flat sheet.

5. Conditions of Warranty

If any following items can't be satisfied, the above warranty shall be invalid.

(1) Before installing and operation, the membrane element shall be stored in original packing box ( the storage of wet membrane element should follow KeenSen “Product Use and Maintenance Manual” chapter one 3.2 “membrane element storage” ), keeping the membrane element sealed in the package, keeping the package away from direct sunlight, the optimal storage temperature shall not exceed 45℃ or 113℉ for dry type and between 0- 45 ℃ or 32-113 ℉ for wet type.

(2) Feed Water Temperature shall not exceed 45℃ , turbidity shall not exceed 1.0NTU、 SDI15≤5 ( 15min、30psi ) .

(3) During installing, operating, or cleaning, the membrane element shall not be subjected to any physical impact that may damage the membrane element, such as load shock, vibration, pulsation, air or water hammer etc. Under any circumstances, the back-pressure that exerted on the membrane element should not be more than 0.03MPa( 4.35psi ) ,which means the pressure of permeate flow higher than feed or concentrate water.

(4) pH range of feed water for membrane element during continuous operation should between 3-10, pH range of feed water for membrane element during chemical cleaning should between 1-13 ( the value subject to the KeenSen latest product manual ) .

(5)NO harmful substance that may cause physical and chemical damage to the membrane element, such as:

a) Nonionic or cationic surfactants, coagulants, organic solvents, oils, lipids, polymers, scratch solids, etc.

b) Chlorine, ozone, potassium permanganate, hypochlorite ions and other oxidizing substances.

(6) Can not be polluted by particles, precipitates, suspended solids, microorganisms, colloidal substances, chemical agents and other substances that may affect the performance of membrane element.

(7) The failure of the chemical dosing system or the ineffective antiscaling measures (for example: Ca, Ba or Sr scaling) or the soluble silicon content in the concentrated water of the membrane system is higher than 150mg/L at 25°C, which makes the scaling difficult to clean chemically off.

(8) Due to the influence of membrane element or membrane system feed water quality (including but not limited to: solution, feed liquid, solvent, etc.), such as: one or more indicators exceed the allowable range (see KeenSen “Product Use and Maintenance Manual” Chapter 5 "Membrane System Feed Water Quality Requirements") or other chemical substances, make the components or accessories of the membrane element (including but not limited to: effective functional layer of the membrane element, end cover, center pipe, glass fiber outer layer, concentrated water sealing ring, central pipe connector, etc.) are deformed, detached or damaged, resulting in the failure of normal use of the membrane element.

(9) In the standard conditions, if the performance of membrane system or membrane element (such as permeate flow, rejection rate etc.) lower down 10%, or the contamination or scaling occurs, the membrane element should be chemical cleaned immediately in accordance with correct method.

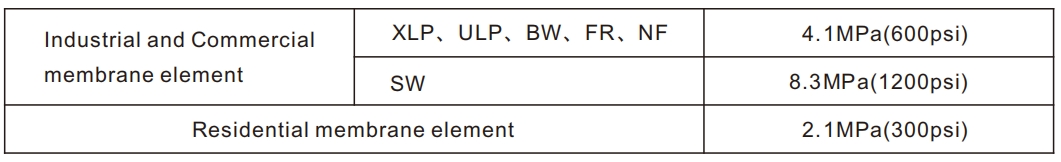

(10) Max working pressure (Subject to the KeenSen latest product manual)

(11) System configuration and design parameters such as membrane array, recovery rate, instrument and meter configuration shall be consistent with reasonable engineering design, and ensure the effectiveness and accuracy of instruments.

(12)The sellers shall be responsible for providing the latest KeenSen product manual to the users, It's necessary to have a good training before their actual operation, the user or operators must have the general knowledge about performance of membrane system or membrane element, they are required to master the necessary knowledge of use, operating the membrane systems or membrane elements, and have the ability of maintenance and accident diagnosis.

(13)The users or operators shall systematically record the standardized operating data of whole membrane system or membrane element regularly, ensure that these data are true, complete and continuous, and keep these data on file, for future analyzing the cause of the fault, and enjoying the quality warranty.

(14)Membrane sheet should be stored in a dry and dark environment, and the storage temperature must be controlled at (5-30) ℃.

(15)Membrane sheet should be used up within 90 days after receipt. If it exceeds 90 days, the performance and color of the membrane sheet may change.

(16)During use and testing, it is strictly forbidden to touch or squeeze the front side of the RO flat to avoid physical damage to the ultra-thin separation layer of the RO flat, resulting in performance degradation.