COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Case Details

Project Overview

The water source of the reclaimed water reuse system in a coal chemical industrial park in Huaibei, Anhui Province, is a mixture of power plant circulating wastewater and industrial wastewater. The industrial wastewater mainly consists of production and domestic sewage from enterprises in the Huaibei new coal chemical synthetic materials base park. After biological treatment by a newly built wastewater treatment plant, the wastewater meets the Class A standard of the "Discharge Standard for Pollutants from Urban Wastewater Treatment Plants". The overall treatment scale of the reclaimed water reuse system is 20000 m3/d, with a total of 4 reverse osmosis membrane systems. Three of them use KeenSen BW-8040FR membrane elements, while one uses imported Fouling-Resistant membrane elements for comparison. There is no significant difference in the operation indicators of the membrane systems, which has been well received by the owner.

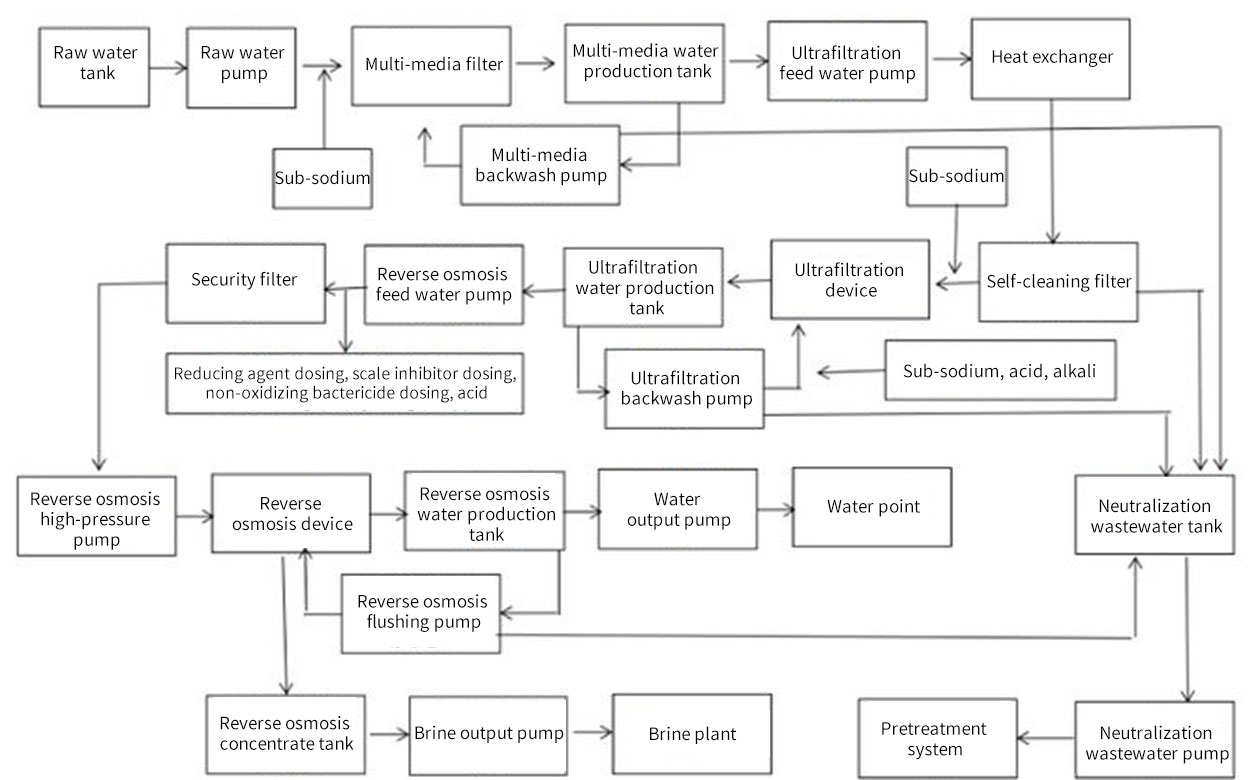

Treatment Process

Project Information

| Model |

Design Capacity LMH |

Recovery Rate % |

Operating Pressure MPa |

Rejection Rate % |

Arrangement (Quantity) |

| BW-8040XLFR | 19.10 | 75 | 1.0-1.5 | 98.7 |

34:17 Six-core installation |

No. 370, Minghu Road, Donghong Street, Xiangjiang New Area, Hunan,China

Scan the QR code to follow the WeChat official account